Whether you are experiencing issues with your Extrusion equipment or machines, we are ready to assist. Our team of experts will diagnose your issues and recommend a corrective action plan to get you back up and running at full capacity while minimizing your down time.

Extrusion equipment maintenance is a must when looking to optimize process efficiency and product quality. Badly damaged or crashed tooling/mold equipment will inevitably lead to expensive repairs and prolonged down time. Small issues can evolve quickly and before you know it a small issue that could have been prevented with regular maintenance turns into a complex problem that halts your operations and costs you thousands. Not to mention that malfunctioning equipment can compromise product quality and performance, a crucial aspect especially when trying to meet stringent OEM benchmarks. Preventive maintenance on your machines and equipment saves you money, helps maintain part quality, helps you avoid unplanned down time, and extends the service life of your equipment and machinery.

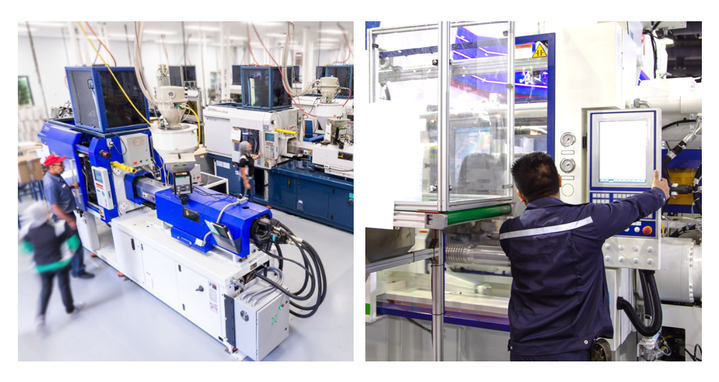

Our extrusion experts have decades of industry experience and can offer specialized in-plant maintenance services that meet all your needs. Our experts have experience with a wide range of extrusion machines and equipment. They are familiar with both domestic and foreign extrusion machines as well as several extrusion applications. They are ready to assist you with the maintenance of your extrusion equipment. All services are conveniently provided on site. Our team of experts can design a custom maintenance package based on your equipment type and requirements. The package may include anything from safety checks and inspections to preventative or proactive maintenance. Specific services provided may include but are not limited to:

Our extrusion experts have decades of industry experience and can offer specialized in-plant maintenance services that meet all your needs. Our experts have experience with a wide range of extrusion machines and equipment. They are familiar with both domestic and foreign extrusion machines as well as several extrusion applications. They are ready to assist you with the maintenance of your extrusion equipment. All services are conveniently provided on site. Our team of experts can design a custom maintenance package based on your equipment type and requirements. The package may include anything from safety checks and inspections to preventative or proactive maintenance. Specific services provided may include but are not limited to:

- Troubleshooting

- Preventative Service and Repair

- Compressed Air Cleaning

- Part and Component Cleaning

- Lubrication and Rust Prevention

- Routine Maintenance

- Welding

- Cavity and Core Repair

- Venting Repair

- Part Design and Construction

- Determining Part Specifications and Part Acquisition

- Water line Inspection, Flush, Drain

- Hot Runner Repairs

- Ejector System Repairs

- Full Refurbishment